粉體行業在線展覽

粉體行業在線展覽

ZK立式旋轉制粒機

面議

般匠機械

ZK立式旋轉制粒機

1699

簡介(Brief):

主要用于制藥、食品行業的制粒,如沖劑顆粒、雞精等。

Mainly applied by pharmacy, foodstuff industry to make granules as dissolved medicines or chicken powders.

不銹鋼制作,主要由旋轉碾刀、篩筒和刮板組成。物料經碾刀碾壓從不銹鋼篩筒的孔中擠出,同時經篩筒外圍的刮板將擠出的物料刮下,形成顆粒。

The machine is made with stainless steel and mainly consists of rotary blades, screen drum and scraper

blades. Materials is extruded from the screen drum by rotary blades, meanwhile, the scraper blades will scrape the extruded materials around the outlet of the screen drum to achieve granules.

二、特點:

其優點是采用旋轉料盤下料,配備定長切斷刀,效率為搖擺制粒機的2-3倍,并滿足標準,是理想的制粒設備之一。結構簡單、易操作、移動方便。自動卸料,彌補了ZL型斜料斗出料有積料的缺點,可連續操作,部分機型可增配料盤水冷系統。適用于半干狀態的粉料和帶有一定粘性的物料、重要沖劑、食品類固體飲料、雞精等。

Its advantage is that it adopts rotating material tray for cutting and is equipped with a fixed-length cutting knife. The efficiency is 2-3 times that of the swing granulator, and it meets the standard. It is one of the ideal granulating equipment. The structure is simple, easy to operate, and convenient to move. Automatic unloading, to make up for the shortcomings of material accumulation in ZL type inclined hopper, it can be operated continuously, and some models can be equipped with a batching tray water cooling system. It is suitable for semi-dry powders and materials with a certain viscosity, important granules, food solid beverages, chicken essence, etc.

本機采用特制行星減速機構,篩網和整粒刀各自相對旋轉運動,將物料在整粒刀和篩筒之間擠搓,輕松從篩筒上的網孔中形成圓柱條狀,在篩筒外的切割刀割下下形成大小均勻,長度一致的顆粒,其顆粒的大小長度由篩筒網孔徑和切割刀把數間隙來決定。

This machine adopts a special planetary deceleration mechanism, the screen and the whole grain knife rotate relative to each other, and the material is squeezed between the whole grain knife and the screen cylinder, and it is easy to form a cylindrical strip from the mesh on the screen cylinder. The outer cutting knife cuts down to form particles of uniform size and length. The size and length of the particles are determined by the aperture of the screen cylinder and the number of cutting knifes.

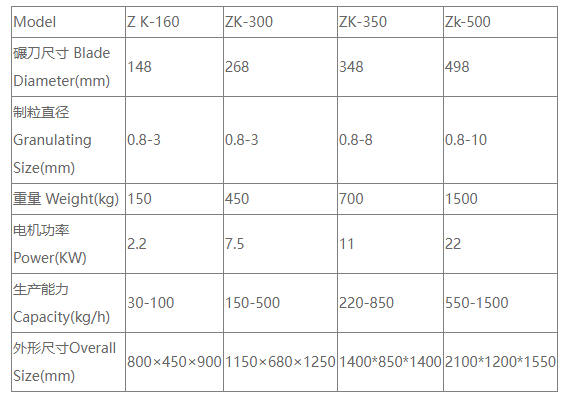

技術參數(Technical Specifications):