粉體行業在線展覽

粉體行業在線展覽

略

面議

核威環保

略

5227

產品詳情

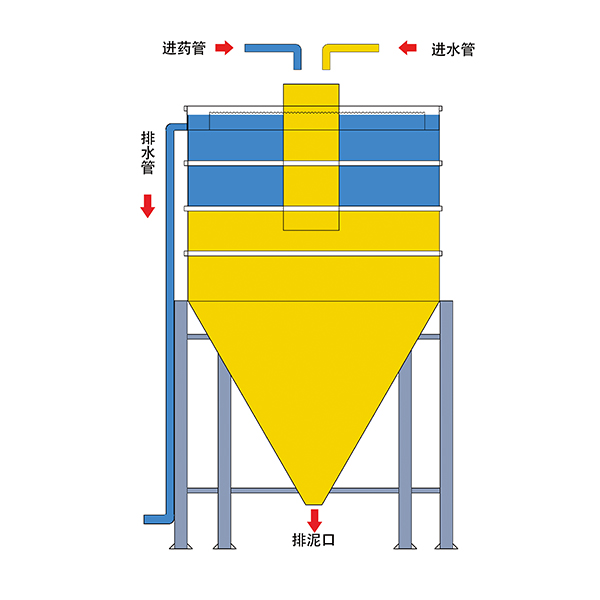

高效深錐濃縮機工作原理

主要特點

處理量大,單臺處理量**可以處理1000方污水每小時,底部外排固體濃度高、運行費用低,占地面積小,投資省,節電,運行費用低,操作簡單,管理方便。溢流水的質量能輕松達到國家排放標準或中水回用標準。因此它非常受各大型礦山,洗砂場客戶的青睞。

Working principle of high efficiency deep cone thickener

Features

Large production capacity, the maximum production capacity of a single unit can be 1000 cubic meters of sewage per hour. Bottom discharged with high solid concentration, low operation cost, the floor area is small, low investment, energy conservation, easy operation, and the management is convenient. The quality of overflow water can easily meet the national discharge standard or reclaimed water reuse standard. Therefore, it is very popular with customers of large mines and sand washing fields.

型號Model | 直徑Diameter(mm) | 罐身Tank Body(mm) | 錐高Cone Height(mm) | 總高Total Height(mm) | 容量Volume(m3) |

GSN3000 | 3000 | 9000 | 2390 | 12530 | 70 |

GSN3800 | 3800 | 7500 | 3074 | 12574 | 97 |

GSN5700 | 5700 | 7500 | 4676 | 14176 | 231 |

GSN7600 | 7600 | 6000 | 6321 | 14321 | 368 |

GSN9500 | 9500 | 4500 | 7880 | 14380 | 505 |

洗砂污水處理工藝流程

文字說明

洗砂機排出來的污水通過1號排水管進入泥水中轉池,由渣漿泵通過2號泥水輸送管抽至濃縮罐,泥漿水進入濃縮罐的同時,3號進藥管也把藥劑抽至濃縮罐使泥水與藥劑混合,泥水與藥劑混合反應后泥漿就快速沉淀,清水溢流通過4號排水管排進清水池以備回用,可用于清洗設備與洗砂或排放,5號排水管排清水進藥劑池用于溶解藥劑。6號排泥管通過濃縮罐底部閥門控制把沉淀濃縮好的泥漿排進壓濾機,并同時通過7號藥劑管把藥劑抽到管道混合器進行絮凝后,進行壓濾脫水,*后脫水后的泥餅通過輸送帶送至泥餅堆場進行堆放或裝車外運,8號清洗水管是用來清洗濾帶,壓濾機壓出來的水與清洗濾帶的水通過設備地基進行收集,再通過9號水管排到泥水中轉池進行余藥利用再一起把泥水抽至濃縮罐進行泥水分離。泥漿沉淀清水排出,以此循環。洗砂污水零排放,清水回用,泥餅回填或外運。

Sand washing sewage treatment process

Description

The sewage discharged from the sand washing machine through the No.1 drain pipe to the mud water transfer tank, and pumped to the concentration tank through the No.2 pipe by the slurry pump. At the same time, the No.3 feed pipe also pumps the chemical to the concentration tank to mix the mud water and the chemical. After the mud water and the agent mix reaction, the mud quickly settles. The clear water overflows into the clean water tank through the No.4 drain pipe for reuse, it is for cleaning equipment and sand washing or discharge, No. 5 drain pipe discharges clear water into the tank for dissolving chemicals. No.6 mud discharge pipe is used to discharge the settled and concentrated mud into the filter press through the control of the valve at the bottom of the concentration tank, and at the same time, the chemical is pumped to the pipeline mixer through No.7 pipe for flocculation,then to the equipment for dehydration. Finally, the filter cake is sent to the storge yard through the conveyor belt for stacking or loading and transportation. No.8 water pipe is used to clean the filter belt, The water from the filter press and the water for cleaning the filter belt are collected through the equipment foundation, and then discharged to the mud water transfer tank through the No.9 Water Pipe for the use of residual chemicals, and then the mud water is pumped to the concentration tank for mud water separation. The mud settles and clear water is discharged to circulate. Zero discharge of sand washing sewage, reuse of clean water, filter cake shall be backfilled or loading out.

以上是關于Tags:高效深錐濃縮機廠家,高效深錐濃縮機價格,高效深錐濃縮機哪家好的詳細介紹

地區產品: 湖北高效深錐濃縮機,江西高效深錐濃縮機,云南高效深錐濃縮機,四川高效深錐濃縮機,廣東高效深錐濃縮機,湖南高效深錐濃縮機,福建高效深錐濃縮機,安徽高效深錐濃縮機,河南高效深錐濃縮機,內蒙古高效深錐濃縮機。